In the world of scientific research and higher education, the pace of innovation is accelerating—and so are the demands on lab operations. Right now, we’re having some of the most exciting conversations with institutions about how to fundamentally change the way labs manage inventory, procurement, and safety. The questions we’re getting are direct: “How can we make our labs safer? How do we save time and money? Is there a way to automate the tedious stuff so our scientists can focus on research?”

There sure is, and it can happen sooner than you think.

The Fourth Industrial Revolution in the Lab

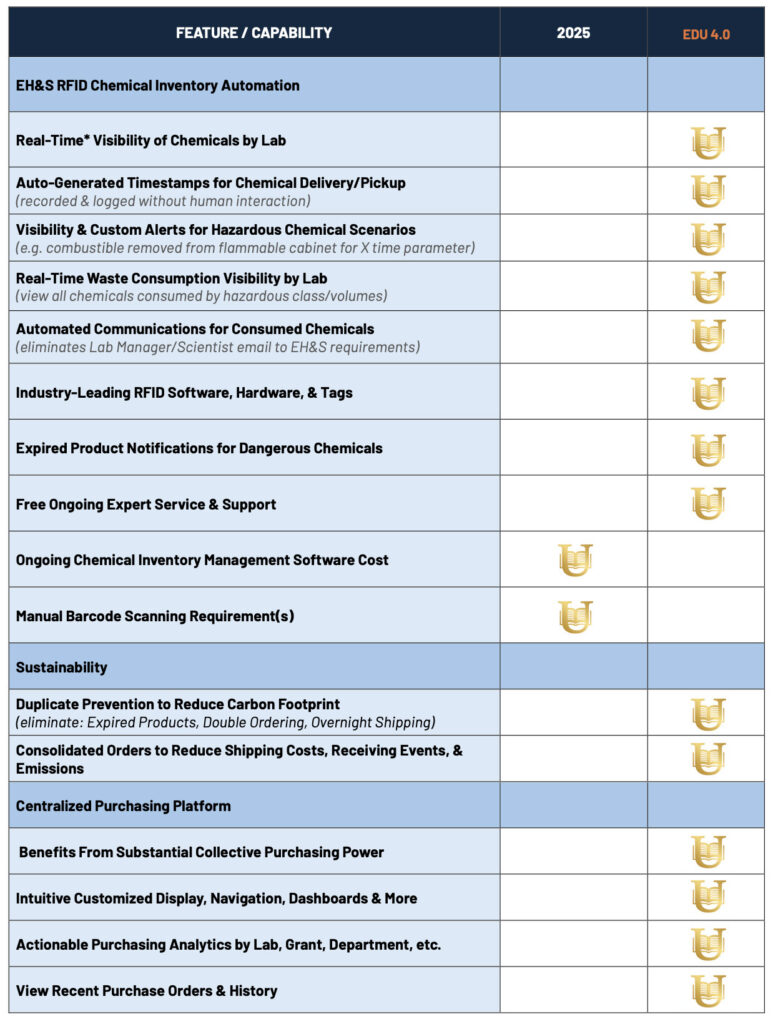

We’re in the midst of the fourth industrial revolution, where cyber-physical systems, IoT, cloud computing, and artificial intelligence are converging to create smart facilities. In our work, we’re deploying real-time RFID chemical inventory management and centralized procurement platforms that bring these technologies to life in academic labs.

What’s Changing?

- Real-Time Chemical Tracking: Instead of manual logs and barcode scans, labs are moving to RFID-tagged containers and automated readers. This means instant visibility of every chemical, automatic alerts for hazardous scenarios, and real-time waste monitoring.

- Automated Safety & Compliance: Systems now send proactive notifications when hazardous waste is ready for pickup, or when chemicals are stored improperly or near expiration. This reduces risk, improves compliance, and eliminates manual checks.

- Centralized Procurement: Historically, lab purchasing has been fragmented, with researchers shopping across dozens of vendors and platforms. We’re streamlining this with unified ordering systems—think Amazon-like interfaces, but for scientific products. The result? Consistent pricing, transparent purchase history, and actionable analytics for every lab, grant, and department.

The Impact: Millions Saved—And That’s Just Purchasing

The financial impact is staggering. By leveraging collective purchasing power and automating inventory, institutions are saving millions of dollars annually—just in purchasing. It’s a stark shift from what we still regularly see at universities: labs purchasing through dozens of supplier websites, with multiple logins (sometimes shared amongst multiple individuals – a cardinal sin), and no visibility into their overall purchasing trends.

Add to that the time saved from eliminating manual inventory, reduced rush shipping, and fewer expired or double-ordered products, and the value multiplies. Safety is improved, compliance is easier, and researchers spend less time on paperwork and more time on science.

Why Now?

Institutions are asking for solutions that don’t just promise savings—they want proof. That’s why we’re seeing rapid adoption: the model is low friction, with no upfront costs, and the savings are immediate. The only investment required is a bit of time from key staff to approve installations and make procurement decisions. From there, automation and centralized purchasing take over, delivering results in weeks, not years.

No Longer Theoretical, But Actionable

The conversations we’re having aren’t just about technology—they’re about transformation. Lab managers, EH&S teams, and finance departments are coming together to rethink how labs operate. The questions are bold, and the answers are actionable.

If you’re ready to explore how automation can make your institution safer, more efficient, and dramatically more cost-effective, let’s talk. The future of lab operations is here—and it’s saving millions.